Vivad's History

Home /

About Us / History

The History of Vivad by Founder Ewen Donaldson

2024:P5 Flatbed

In 2025 We Installed a Durst P5320HS Flatbed digital printer to handle our increasing volume of fladbed print

2024: Durst Rhotex ISub

In 2024 We Installed a second Dye Sublimation 3.2 metre wide printer to double our fabric printing capacity

2024: Colorado M5

In 2024 We installed a Canon Collerado M5 UV Gel printer

2023: Mattic Helios Plus Laser Cutter

In 2023 We installed the Hellios Mattic laser cutter to cut all of the fabric print we produce

2022: 500sqm Mezzanine

In 2022 We built a 500 SQM Mezzanine to expand our fabric sewing department as well as contain our print room in a temperature controlled environment

2020: Covid-19

A year we will never forget, the covid19 pandemic decimated the exhibitions and events industry and destroyed the livelyhoods of many.

2019: Launch of the new Logo

2019: The Launch of Vivtrack 3

After 2 years of listening to user feedback we have completely rewritten our web to print Portal Vivtrack 3 to help improve our digital & banner printing.

2019: Durst 512R LED

First week back in 2019 and Vivad commissioned our second 5 metre wide Durst. The Dusrt 512R LED Roll-to-Roll. The quality and speed of this machne is outstanding, and complimenting our existing 5 metre wide Durst 500R, this machine increases our capacity and provides redundancy for our existing 5 metre wide offering.

2018: Bullmer 5 Metre Cutter

In October of 2018 Vivad installed the first Bullmer 5 Metre cutter in Australia. Increasing demand and production efficiencies called for 5 metre cutting capabilities. Vivad could now use two machines for cutting print jobs which reduced bottlenecks and increased through put.

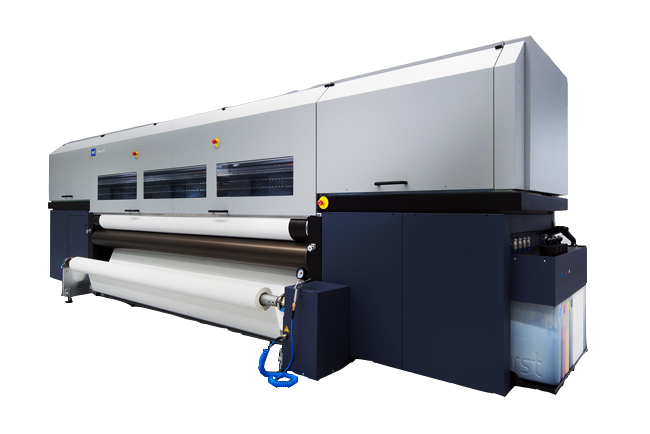

2017: Rhotex Durst

The versatility of fabrics resulted in increased demand, which in turn required increased production capacity. Vivad turned to Durst with the procurement of the Durst Rhotex 325 which can print direct to fabrics or to paper for paper transfer.

2017: Launch of Vivtrack 2

At Pacprint 2017 Vivad launched Vivtrack 2 which is our proprietary web-to-print solution which allows clients to customise and order their print jobs on-line. In one sitting they can Preflight, Pre-approve and place their orders on-line. For more information see our: Promotional video

2015: The big move

In 2015 Vivad moved from our previous 1200 Square metre factory to this beautiful 3500 square metre factory. With more room to move and more room to grow, the move heralded a new era for Vivad.

2015: HP 360

In 2015 we superseded our two HP 25500 latex printers with 2 new HP360 printers, with more vivid blacks, more speed and better adhesion, the new HP technology was a big step up for the production of our self adhesive vinyl work.

2014: The Teleios Black

To compliment our display and flag printing capabilities and provide a back-up, Vivad purchased the Dgen Teleios black printer.

2013: ATP Colour

In 2013 we purchased this innovative dye sublimation printer from ATP colour which has the unique feature that the Calander is built into the printer. Great for display fabrics the ATP colour printer produces excellent results with a 7 picolitre drop size.

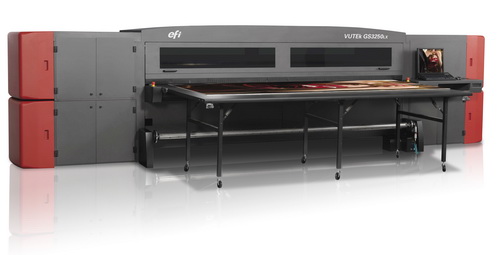

2013: Vutek GS3250LX

In 2013 we upgraded our ailing flatbed printer to the latest in UV cold cure flatbed technology. The Vutek GS3250LX allows us to print using grey scale images at 1000DPI at production speeds. The latest generation of inks offered excellent adhesion to rigid materials such as coreflute, forex and acrylic, as well as offering excellent flexibility for banner and adhesive vinyl. The ink set is truly conformable making it also suitable for vehicle wraps. The new white ink is very opaque, which allows for printing onto coloured stock. For print runs of 1 to 1000, on rigid or flexible stock, where vibrant colours and close viewing distances are required, our Vutek GS3250LX will satisfy even the most discerning clients.

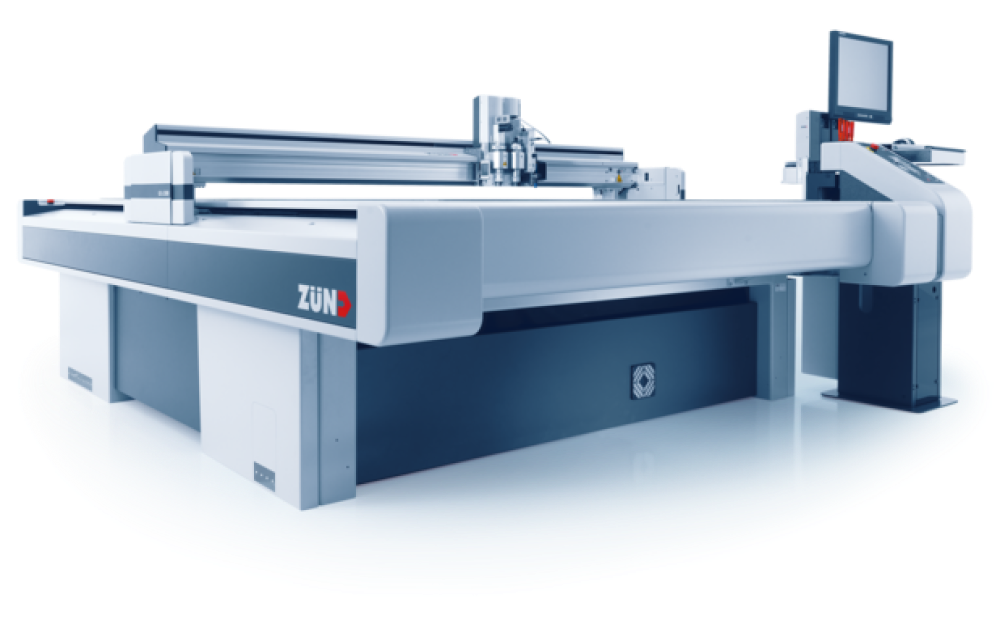

2013: The Zund XL3200

In 2013 Vivad took the plunge into investing in a Zund router cutter to assist in the print finishing capabilities. With this machine we can register the cut line perfectly with the print. The photographic sensor finds registration dots printed around the print and locates the print on the substrate. Armed with a variety of tools heads this machine can cut, crease, route, and score a variety of materials including fabrics, coreflute, foam board, banner vinyl and MDF.

2011: The Durst 500R

In 2011 Vivad purchased our second five metre printer; the Durst 500R. An improvement of UV cured inks meant a step away from solvent based inks which was a step in the right direction from both an OH&S and environmental point of view. UV inks are low on VOCs and the ink cures by the cross linking of polymers rather than the evaporation of solvents.

The Durst 500R can print up to an incredible 400 square metres per hour and because the ink is UV cured, we can print on a wide variety of materials including banner vinyl, polypropylene, textiles, mesh, clear film and adhesive vinyl.

The Durst 500R also has the ability to print with white ink. The introduction of white ink bought about a new process for printing backlit banners called Day/Night backlit printing. The process involves printing three layers, comprising of the image, a layer of white ink and then the image again. This means that the print is more faithful to the design regardless of whether the banner is backlit or frontlit. Traditionally backlit banners would be printed as double strike, whereby twice the amount of ink is laid down. The problem is that if the banner is not being backlit the image is too dark.

2010: The HP L25500

In 2010 Vivad purchased two HP 25500 latex printers. These versatile machines were excellent for printing onto self adhesive vinyl as well as a range of other roll stocks. The great advantage of latex inks as opposed to solvent or eco solvent inks is that they can be laminated straight away without having to wait 24 hours for the ink to outgas.

2010: The Vutek Fabrivu

In 2010 Vivad made it's debut into the fabrics market with the procurement of the Vutek Fabrivu. Soft signage was a term coined for digital print sublimated onto polyester. It was around this time that stretch frame signage started to become popular. At this time Vivad started to develop their own unique stretch frame extrusion designs. A whole range of new soft signage products came into being such as Feathers and Teardrops.

2008: HP Designjet 5000

In 2008 we complimented our production with the addition of a HP Designjet 500 for the production of smaller large format jobs. The designjet used aqueous based inks and would print onto mainly coated paper based stocks.

2005: The Vutek 3360EC

Around the middle of the decade solvent inks still played an important role particularly in the digital printing of truck sides.

The Vutek 3360 bought 8 colour solvent printing to our production capacity. Solvent based pigmented inks offer uniquely vibrant colour and great adhesion to vinyl. The ink is comprised of solid pigment held in a suspension of solvent. The solvent allows the pigment to key into the vinyl's surface as it evaporates off.

2005: The Seiko Colorpainter 100S

Around the middle of the decade, print head technology developed rapidly allowing smaller dot sizes and higher resolutions.

In 2005 Vivad installed a 2.5 metre Seiko Colorpainter 100S, which allowed for high resolution printing up to 2.6 metres wide using a lighter solvent than the hard solvents used in the earlier Vutek machines.

2004: The Vutek PV200SC (2004-2013)

Around 2004 a new ink technology emerged; uv cured inks started to take the place of solvent based inks. This allowed printing on a wider range of substrates including rigid materials like coreflute, forex and acrylic. In 2004 Vivad installed our first Flatbed printer. The Vutek PV200SC. This allowed us to print up to 2 metres wide on rigid materials, as well as roll to roll.

2000: The Roland FJ600 (2001 - 2005)

It wasn't long before we bought a second printer; a Roland 8 colour HiFi jet 7600 Pro, to handle some of our smaller format work.

Printing at 1400 DPI in 8 colour using pigmanted inks, the quality from this printer was exceptional. It was about this time that we put in our first laminator, so that we could apply film laminate to our digitally printed products

2000: The Vutek 5300

Vivad was incorporated in the year 2000, with our first 5 metre superwide format printer; the Vutek 5300. Our primary ambition was to get into the printing of truck sides. The family business; Polyweld was a market leader in the manufacture of truck side curtains for the transport industry. Printing on the sides of trucks was a natural progression given that the technology had come of age.

It soon became apparent that there were more opportunities in large format digital printing than just fleet graphics. Demand for large format extended into other industries including exhibitions, events, retail, architecture, media and other general signage.